How Vehicle Loops Work

Vehicle detection loops are an essential part of access control systems, helping gates, barriers, and doors operate automatically when a vehicle is present. While they are often mistaken for magnetic sensors, loops actually work through induction. When a conductive object such as a car enters the loop's field, the system senses the change and registers a detection. Knowing the basics of how loops function makes it easier to understand their reliability, the types of materials they can detect, and how sensitivity settings affect performance. This foundation will set the stage for exploring the details of induction, detection thresholds, and practical applications throughout this article.

Induction VS Magnetism

Vehicle loops work on the principle of induction, not magnetism. A loop detector measures changes in inductance when a vehicle passes over or stops above the loop. Inductance is created when alternating current (AC) flows through the loop, producing an electromagnetic field. When a conductive object enters this field, it disrupts the balance and changes the inductance, triggering detection.

This is different from magnetism. Materials do not need to be magnetic to be detected. What matters is their ability to conduct electricity. For example, many modern gate materials such as aluminum are non-magnetic but still conductive, and therefore easily picked up by a vehicle loop. In short, loops sense conductive properties rather than magnetic ones, making them versatile and effective across a wide range of vehicle and gate materials.

Different Functions of Loops

Reverse Loops

A reverse loop is designed to send the gate back to the open position when a vehicle is detected. This function greatly reduces the risk of the gate closing on a car, even in cases of tailgating or follow-through. For properties that require higher security and want to prevent vehicles from slipping in behind others, a reverse loop can be paired with a sally port or a barrier arm to add another layer of control.

Exit Loops

An exit loop automatically opens the gate when it detects a vehicle, creating a smooth and convenient way to leave the property. To maintain security, these loops should be buried directly in the ground so they are not visible, and in some cases placed further back from the gate. This setup prevents someone from tossing a conductive object, such as a metal lid, onto the loop to trigger an exit. Exit loops also have the ability to reverse the gate, which means they can serve as an alternative to an inside reverse loop.

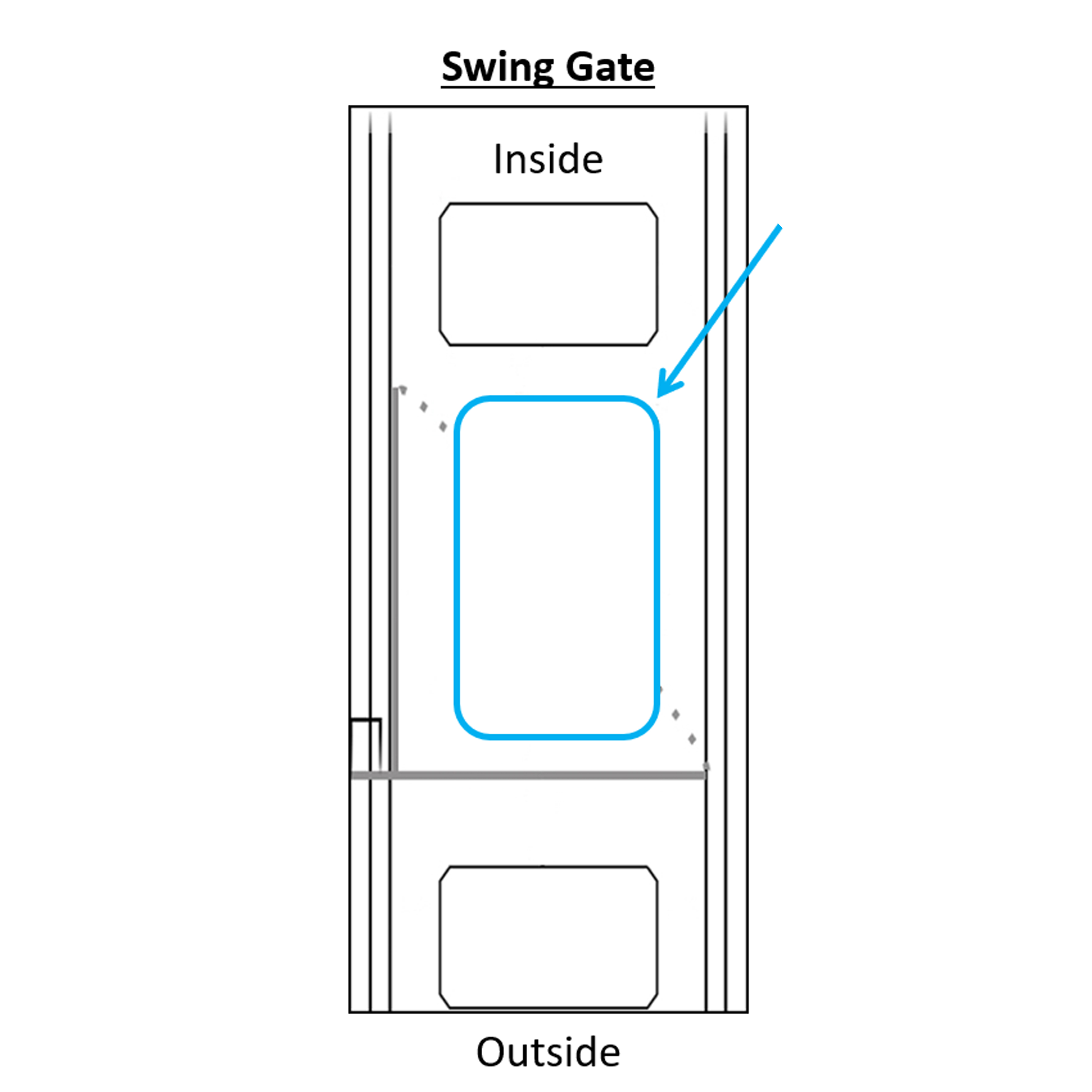

Center or Shadow Loops

The center, also called a shadow loop, is used specifically with swing gates. It is installed beneath the swing path and ensures the gate does not move if a vehicle is detected in its way. Without this safeguard, a vehicle could be struck as the gate opens or closes. Shadow loops are especially important on wider gates. For instance, a 12-foot single swing gate creates about 20 feet of space between the inside and outside reverse loops, a gap large enough for a car to sit undetected unless a shadow loop is present.

Loop Function Terminology

- Reverse Obstruction Interrupt: Reverses a gate that is closing and holds the gate in the open position.

- Exit Automatic Open/Egress: Opens a closed gate automatically when detection occurs. It can also reverse a gate while closing and hold it open.

- Arming Activation: Enables connected equipment to function. Common examples include telephone entry systems, RFID readers, and ticket dispensers.

- Shadow Center Platform: A loop placed under the swing path of a swing gate. It checks for the presence of a vehicle before allowing the gate to close.

Loop Placement Requirements

- 2 feet from every curb

- 4 feet from the gate (5-6 ft for larger gates)

- 4 feet from every other loop

Detection height:

- Roughly 2/3 the short leg of the loop

- Residential: 4 ft short leg (32 inch detection height)

- Commercial: 6 ft short leg (4 ft detection height)

Shadow Loops

- 3-4 feet from the gate in its closed position

- 3-4 feet from the gate in its open position

- 0-2 feet from the curb (if single swing system)

How Many Loops Does My System Need?

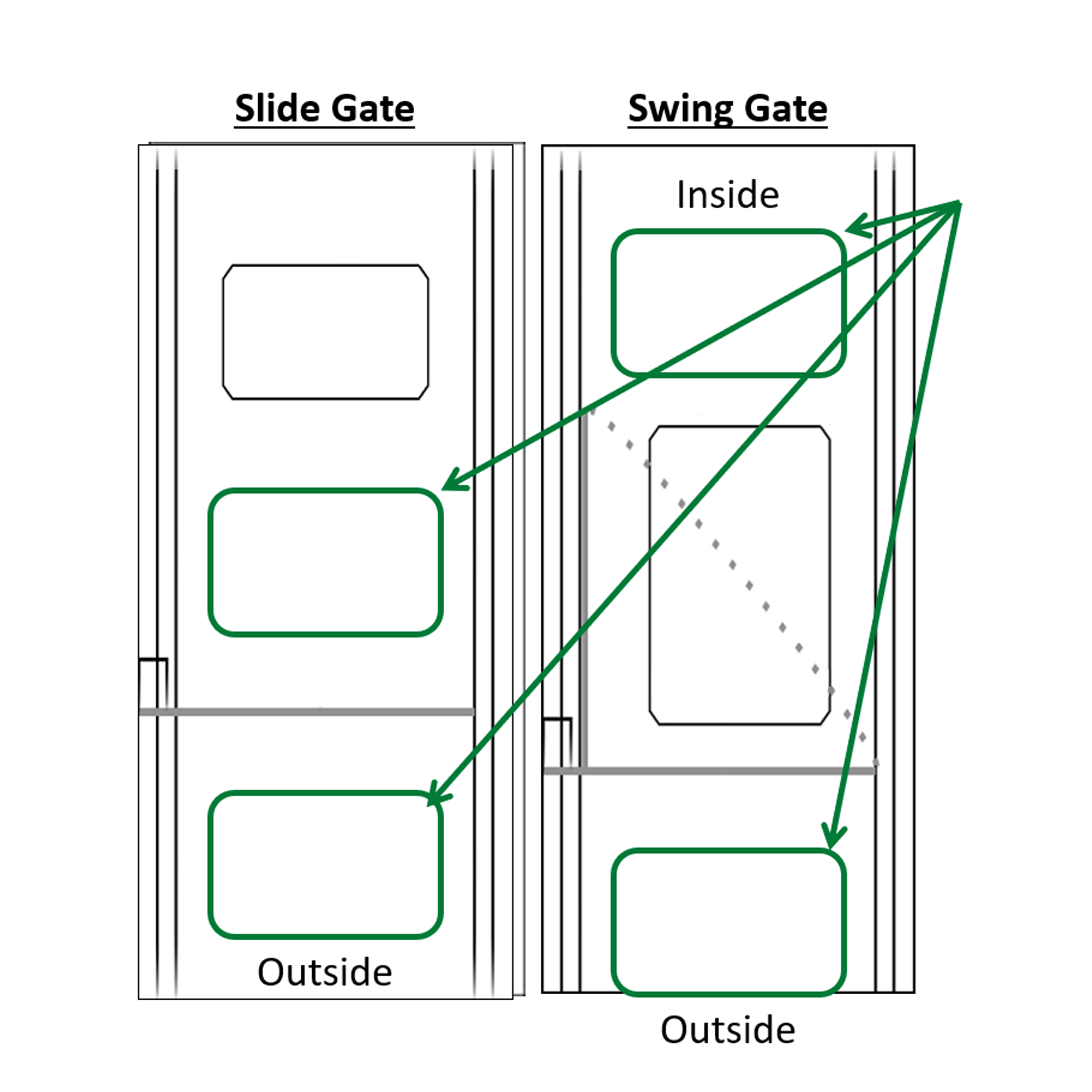

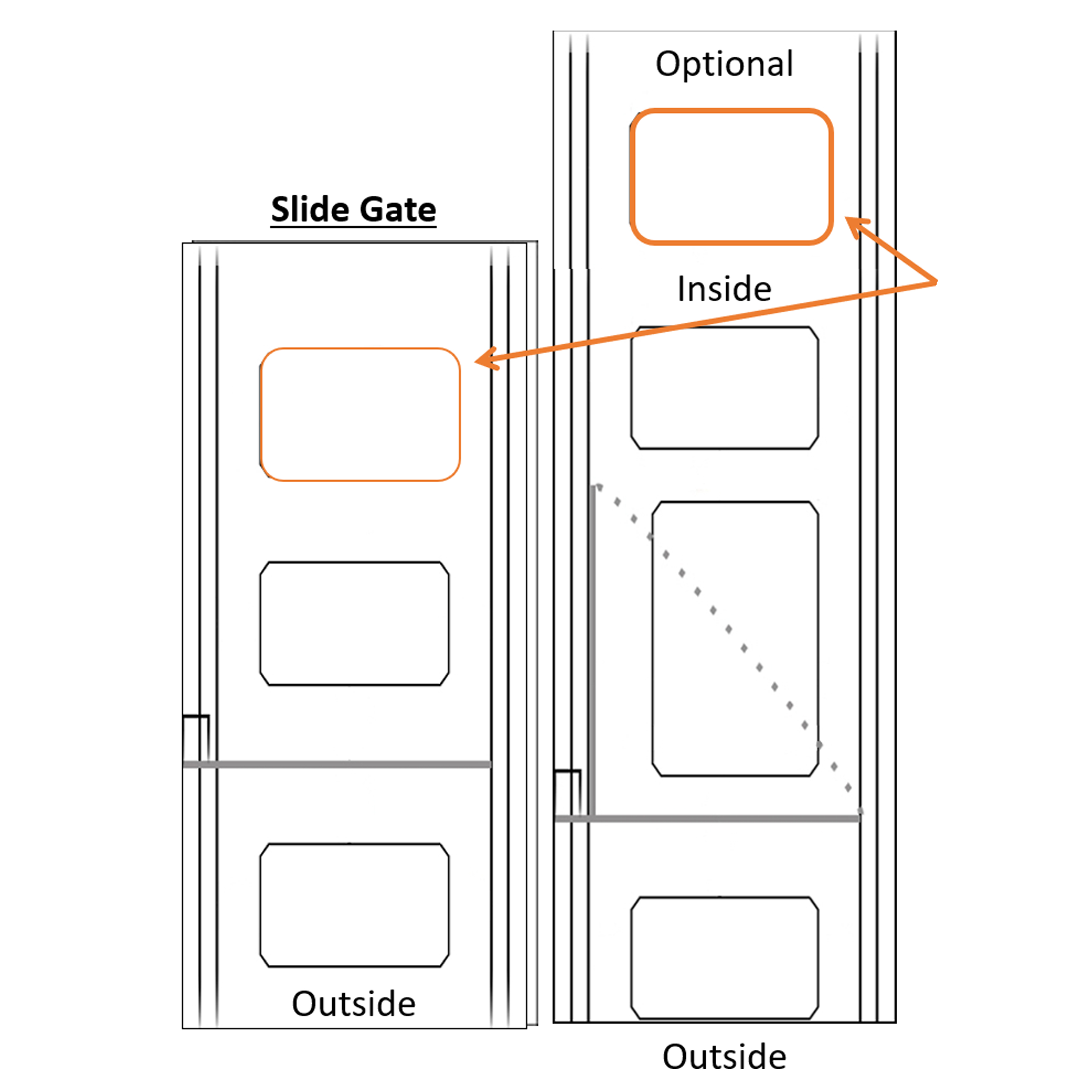

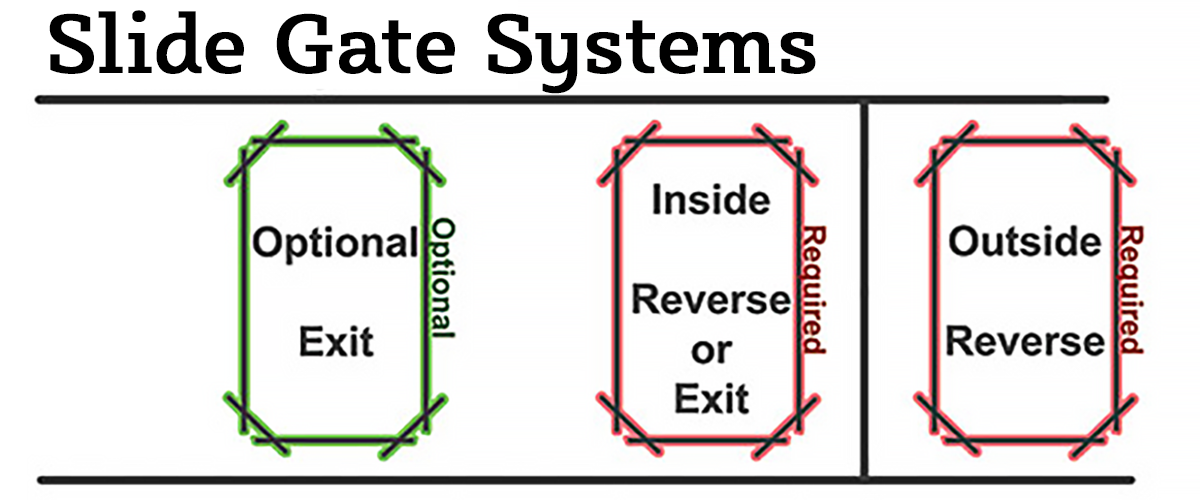

Slide Gate Openers

If you have a slide gate, cantilever gate, vertical lift gate, or vertical pivot gate, you need two loops to fully protect the gate path. If space permits, you may want to install an additional exit loop further down the driveway so the gate will be open by the time the vehicle reaches the gate.

- (1) Inside Reverse or Exit Loop

- (1) Outside Reverse Loop

- (1) Extra Exit Loop (optional)

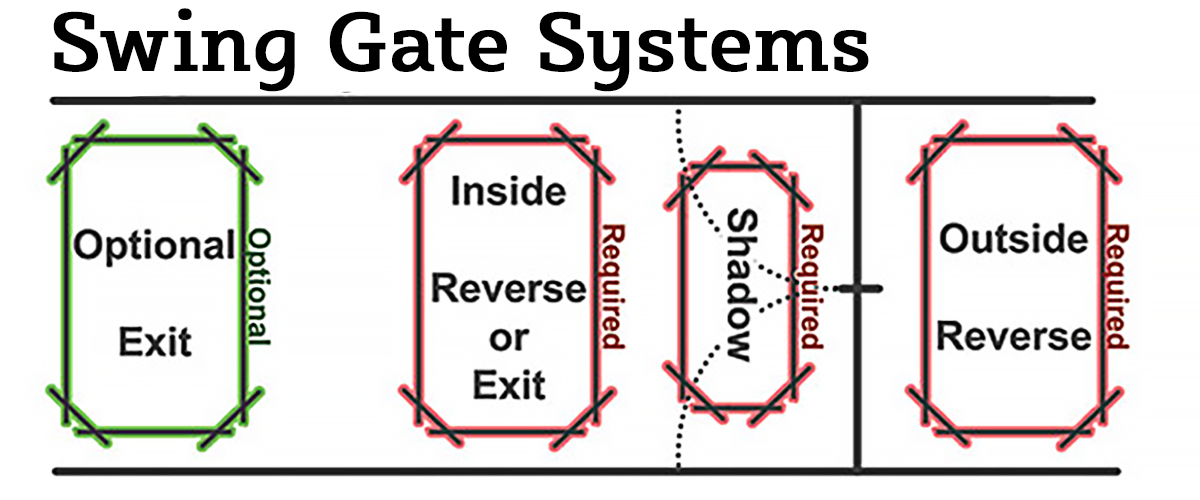

Swing Gate Openers

If you have a swing gate, you are required to have three loops. If space allows, consider adding another exit loop farther down the driveway so the gate is already open by the time the vehicle arrives.

- (1) Inside Reverse or Exit Loop

- (1) Shadow Loop underneath the gate swing path

- (1) Outside Reverse Loop

- (1) Extra Exit Loop (optional)

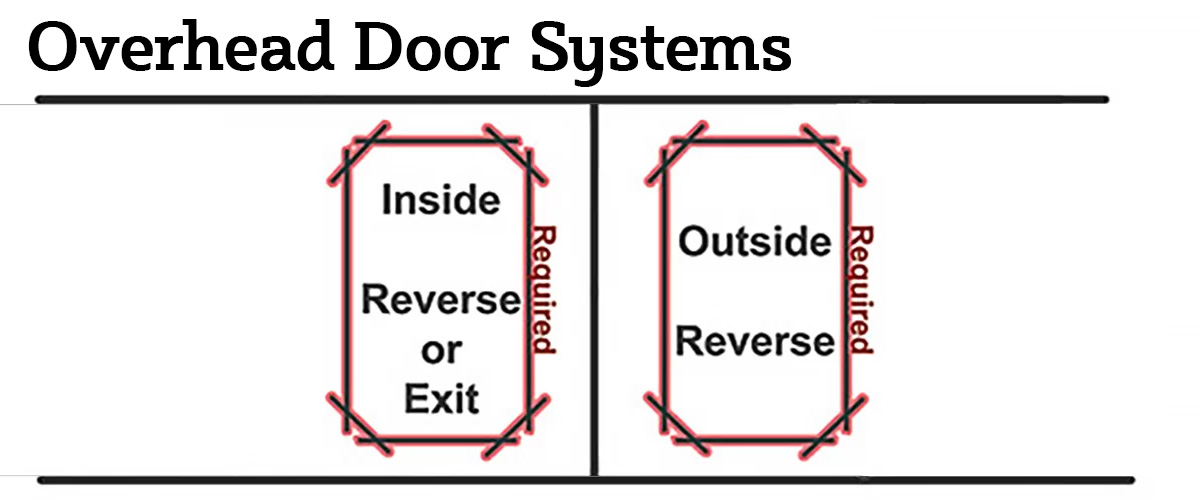

Overhead Door Gate Openers

Overhead doors require a minimum of 2 loops to fully protect the door path. The most common functions that are used for overhead doors include reverse loops and exit loops.

- (1) Inside Reverse or Exit Loop

- (1) Outside Reverse Loop

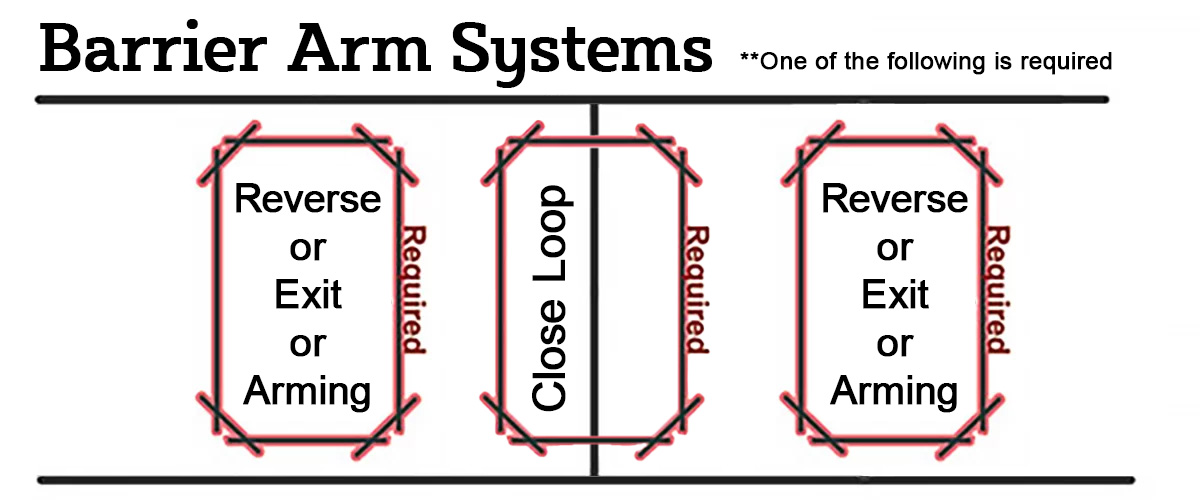

Barrier Arm Gate Openers

If you have a barrier arm gate operator, you are required to have a minimum of 1 loop for fully protect the barrier path. There are more loop function options for gate openers that use barrier arms that are permitted to be used. At least one of the following must be used.

- (1) Close Loop

- (1) Arming Loop

- (1) Inside Reverse or Exit Loop

- (1) Outside Reverse Loop

What is the Difference Between a Reverse and Exit loop?

Exit loops automatically open the gate when a vehicle drives over them. They also will hold a gate open and reverse a closing gate, which means they can be used in place of an inside reverse loop. Reverse loops will reverse a closing gate if a vehicle is detected. A reverse loop will also hold a gate open if a vehicle stops over the loop. If a gate is fully closed and a vehicle drives over a reverse loop, nothing will happen; the gate will not open.

Objects Near the Loops

When a detector is reset, it takes into account all of the metal already present in the area and sets that as its baseline. As long as the metal remains stationary, it does not interfere with detection, since the system is looking only for changes in inductance. This means fixed objects, such as nearby fencing or structures, generally do not cause issues. However, it is important to be aware of certain overlooked items that may fall within a loop's range. A pedestrian gate or a vehicle parked in a space adjacent to the loop can both become points of concern if they shift or move. To avoid false detections, any moving metal object should be kept at least four feet away from the loop.

Loops and Power Lines - Is the Myth True?

It is common for power lines to run beneath a driveway or alongside it, which often makes following standoff guidelines seem impossible. You may have been told to keep loops away from power lines, however that is not necessarily the case. To address this concern, extensive testing has been carried out with loops tied directly to power lines. In every case, detectors showed no cross talk or false detections, even when the circuits were overloaded and the detectors were set to their maximum sensitivity. These results confirm that properly installed loops remain reliable even in the presence of nearby power lines.

Does Wire Gauge Matter With Loop Detectors?

When it comes to inductance loops, wire size makes a real difference. The thinner the wire (higher gauge), the higher its electrical resistance. Increased resistance causes energy loss, which weakens the signal and results in less reliable detections. This issue becomes especially noticeable in larger loops or when there are long runs of lead-in cable, where the added resistance compounds the problem.

To maintain strong and consistent performance, it is best practice to use 16 AWG wire or thicker when installing loops. A properly sized wire ensures the loop maintains signal strength, improves detection accuracy, and helps avoid performance problems over time.

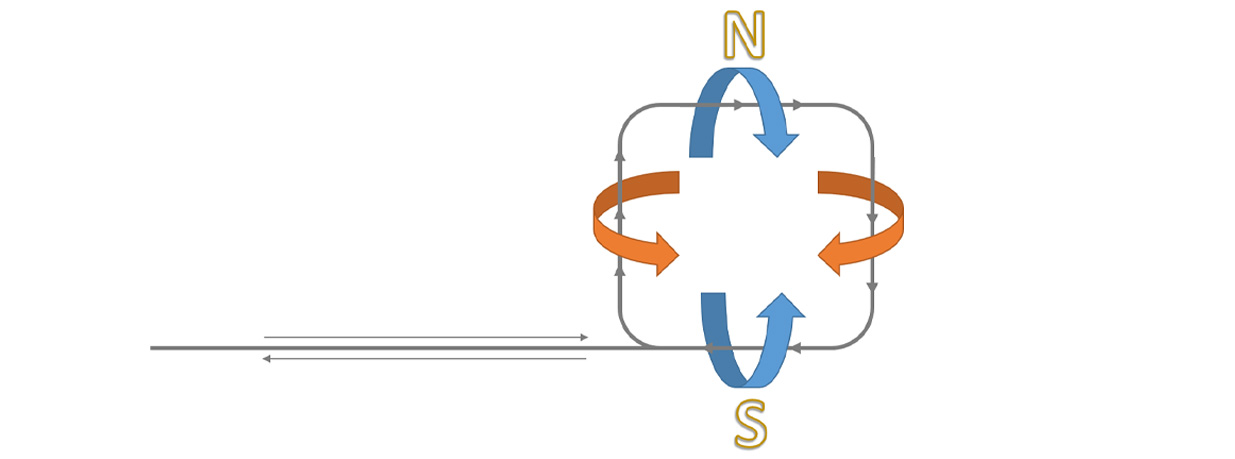

Loop Detection Field

The detectable field created by a loop is an electromagnetic field. Although magnetism is not used, the field behaves like a magnet. When the current flows through the loop, the opposite legs carry current in opposite directions. As a result, the electromagnetic fields attract one another, pulling toward the opposite sides of the loop.

This attraction concentrates the field inward, toward the center of the loop. Most of the detection strength exists directly above and below the loop itself, which is why a vehicle generally needs to drive close to or directly over the loop to trigger detection. The detectable range does not extend far beyond the loop's footprint, making proper placement critical for accurate performance.

Loop Design and Detection Height

The depth at which a loop is installed affects how it performs. Loops that are buried deeper in the ground are less sensitive than those placed closer to the surface.

- Direct burial loops are typically installed 6-8 inches deep but can still function at depths up to 14 inches, although sensitivity decreases with depth.

- Saw-cut loops are usually installed at a depth of 1 1/4 to 1 1/2 inches, providing stronger sensitivity since they are closer to the surface.

Detection height is determined by the short leg of the loop, which defines how far above the surface a vehicle can be detected. The detection height equals roughly two-thirds of the length of the short leg, with a maximum limit when the short leg reaches eight feet.

Examples include:

- A 4-foot short leg provides about 32 inches of detection height.

- A 6-foot short leg provides about 4 feet of detection height.

- An 8-foot short leg reaches the maximum detection height achievable with a loop.

- Loops with a short leg smaller than 4 feet will have limited detection height, making them less effective for certain applications.

Loop Sensitivity

Loop sensitivity is influenced by a range of factors, and it plays a critical role in whether a system can detect different types of vehicles consistently. A loop that easily picks up a large work truck may not detect a smaller car or motorcycle with the same reliability. One of the most common issues is lead-in length: the longer the lead-in, the less sensitive the loop becomes. While it may be tempting to simply set the detector to its highest sensitivity to compensate, this approach can actually create more problems, such as false detections or unstable performance.

Several variables work together to determine how sensitive a loop system will be:

- Depth and size of the loop

- Vehicle type, such as residential passenger cars compared to larger commercial vehicles

- Detector sensitivity settings

- Whether multiple loops are connected in series

- Total lead-in length

In cases where a loop requires an exceptionally long lead-in (200 feet or more), it may be necessary to add a winding to the loop to maintain sensitivity. For these installations, choosing a detector with a wide sensitivity range is strongly recommended, as it provides the flexibility needed to fine-tune performance for the specific site conditions.

For More Information On Loop Sizes, See Our Loop Size Chart For Reference.

About Direct Burial Loops About Saw-Cut LoopsVehicle detection loops play an important role in ensuring the safety, security, and convenience of access control systems. By understanding how loops work, the difference between induction and magnetism, and the impact of factors such as placement, wire size, and sensitivity, you can design a system that performs reliably for years to come. Whether you are working with swing gates, slide gates, overhead doors, or barrier arms, choosing the right loop setup is essential to achieving both efficiency and protection.

If you need help selecting the correct loop size, configuration, or detector for your project, do not hesitate to contact our expert sales team. We are here to answer questions, provide recommendations, and help you get the most dependable performance from your access control system!

Contact Us