What Is DASMA?

Door & Access Systems Manufacturers Association International, or DASMA for short, was established in 1996. It was the result of the consolidation of two of the industry's largest manufacturer associations; the Door Operator & Remote Controls Manufacturers Association (DORCMA) and the National Association of Garage Door Manufacturers (NAGDM). These two organizations have roots all the way back to 1959, when garage door openers were becoming prevalent in America. DASMA is a standards development organization that is accredited by the American National Standards Institute (ANSI). They have developed a variety of standards for the industry, of which several have been approved by ANSI. In 2006, the American Rolling Door Institute (ARDI) merged into DASMA.

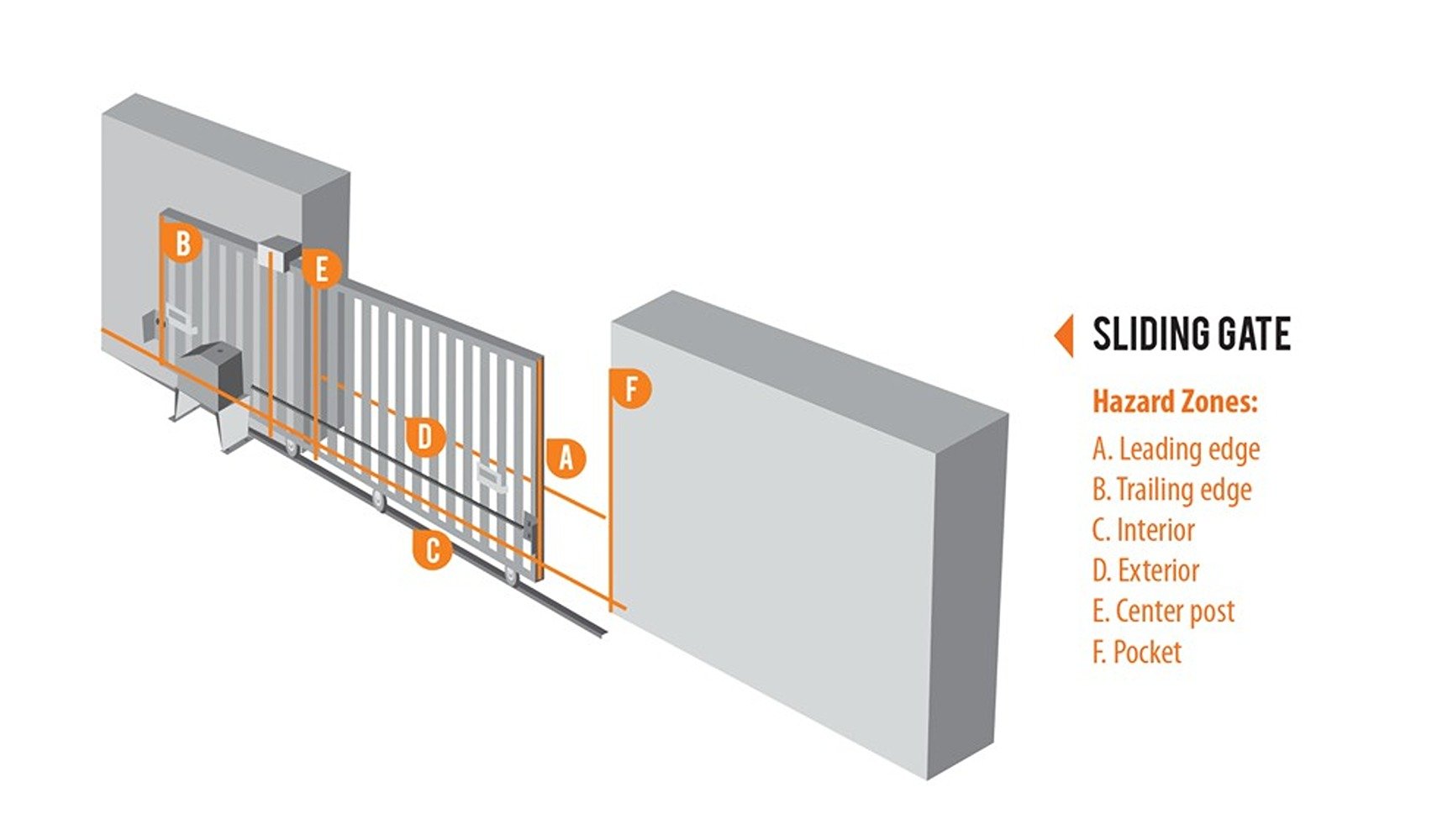

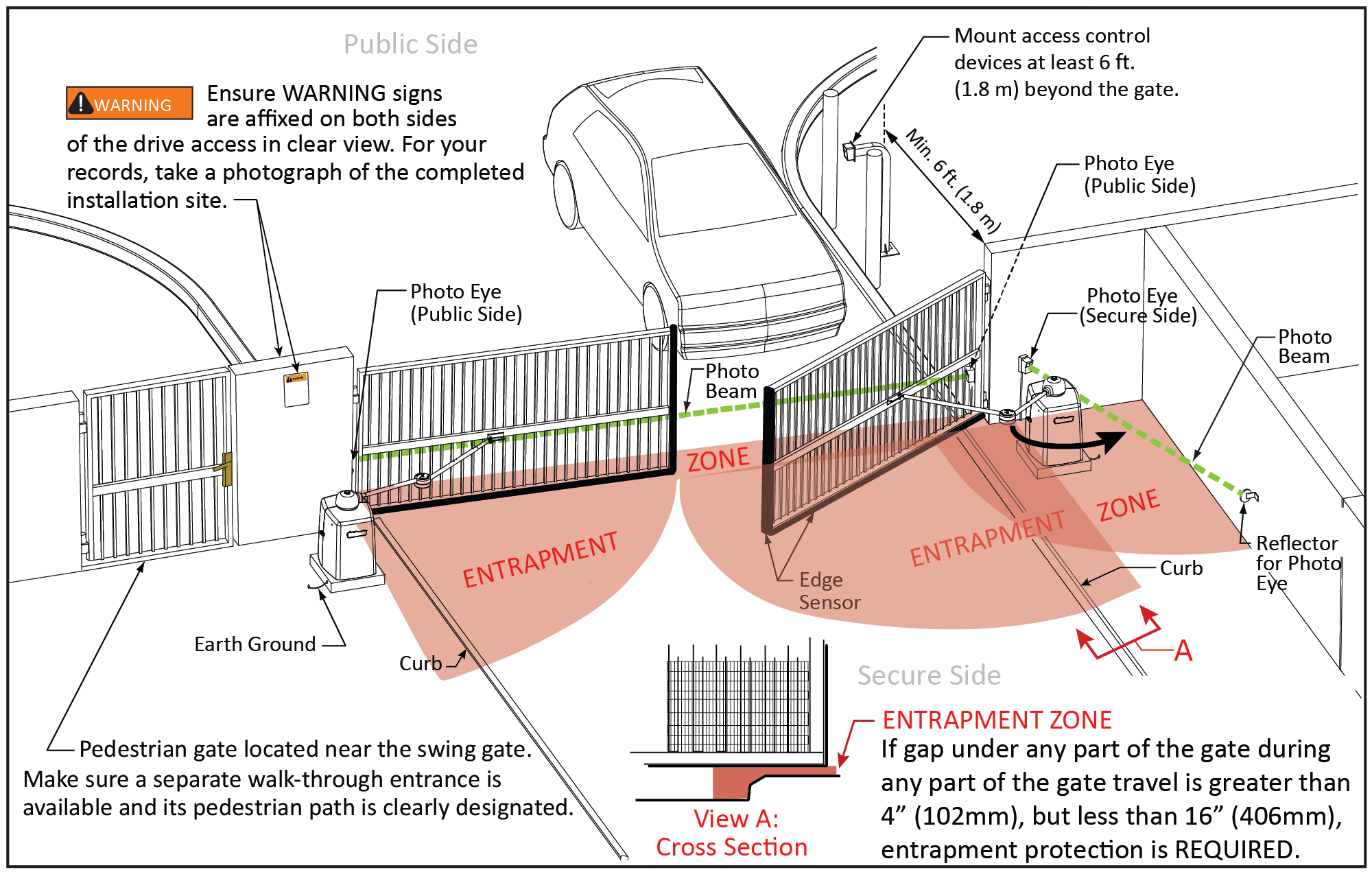

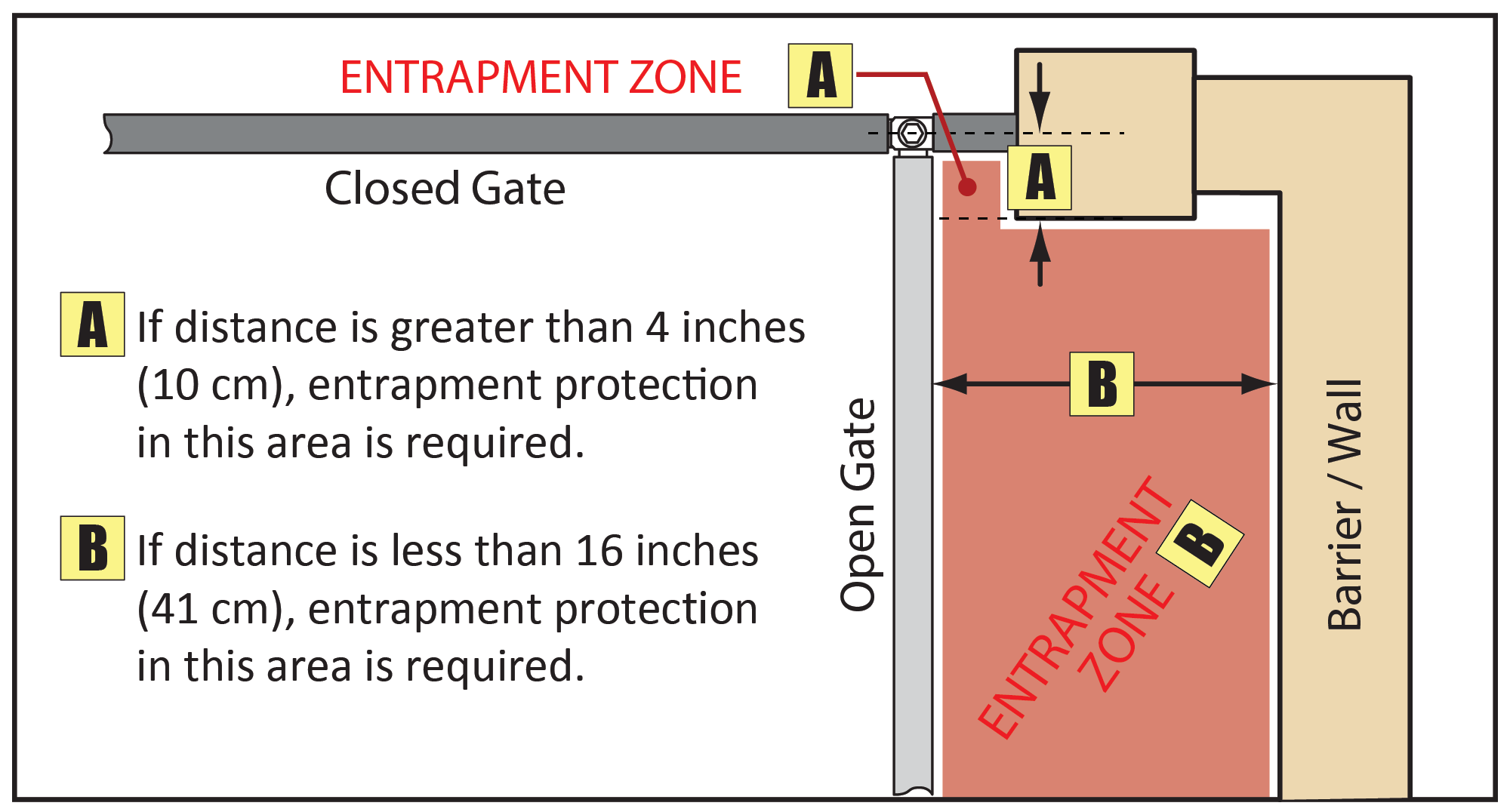

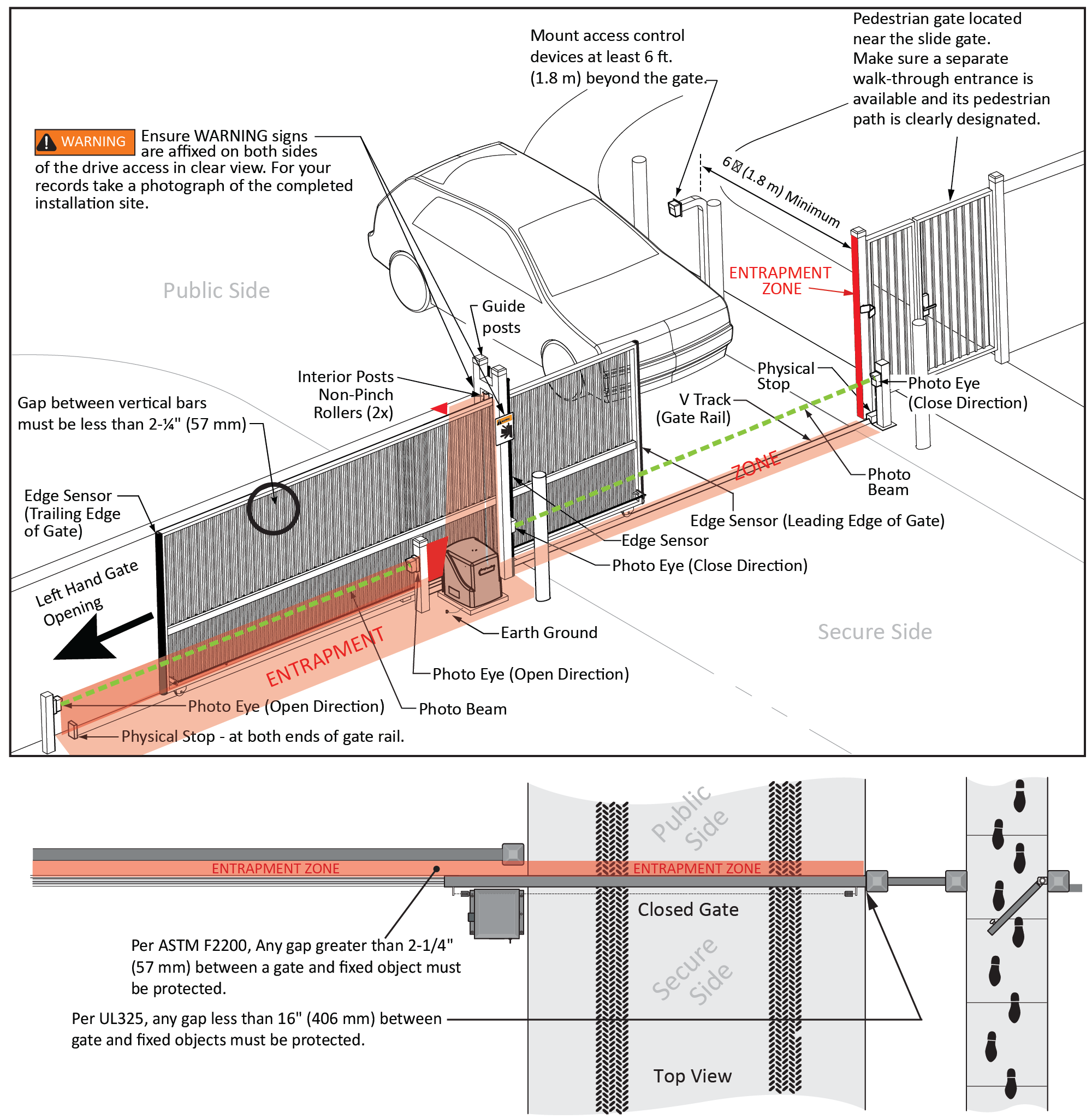

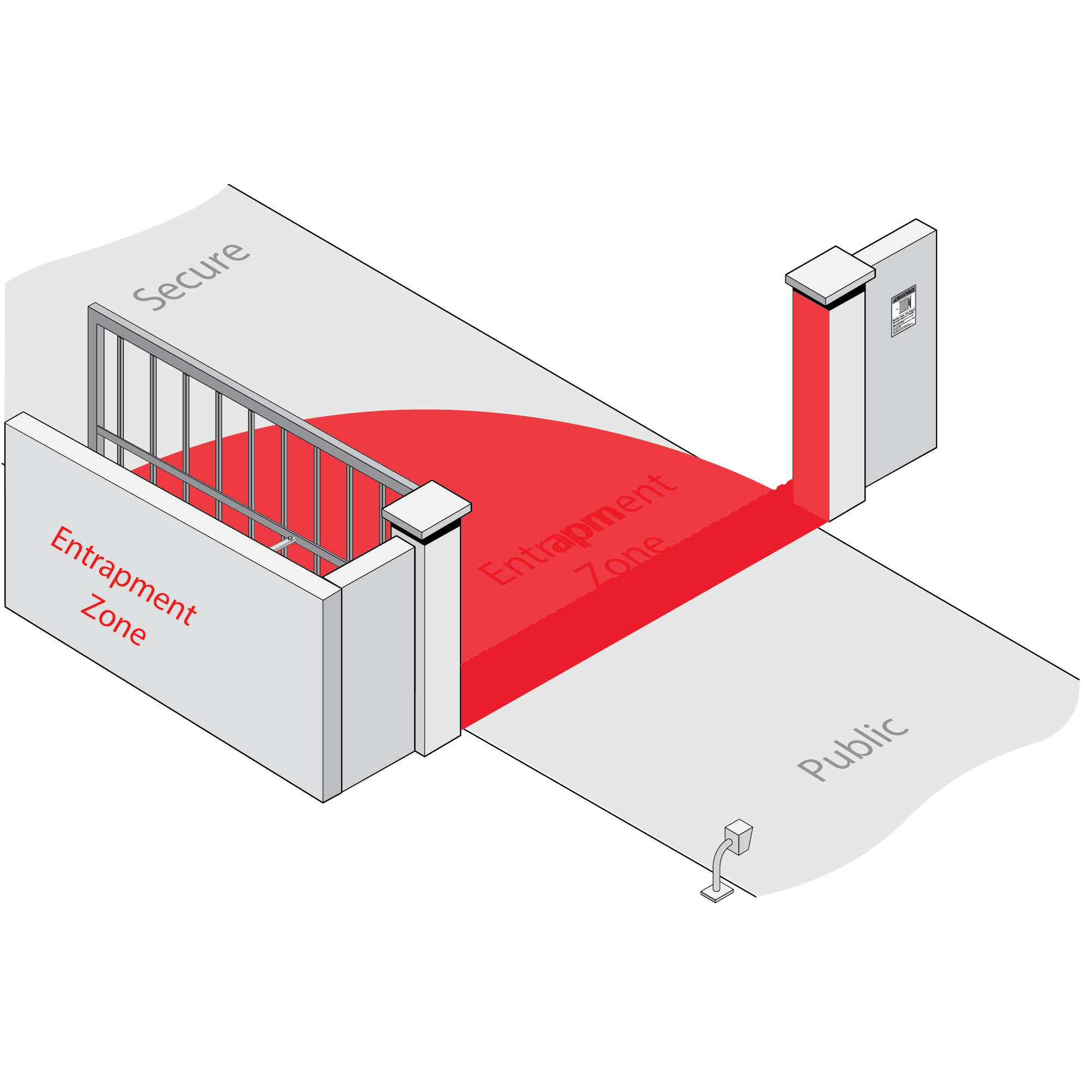

There are several requirements for the different types of gates. Check out the diagrams as well as pdfs to make sure you're installing a slide or swing gate according to the safety standards of DASMA.

Swing Gate Requirements

Only install the operator on gates used for vehicular traffic. Be sure to direct pedestrians to a separate entry and exit. Refer to the illustrations. The gate site must be designed, so persons do not come in contact with the vehicular gate while it is moving. Signs must be posted to warn pedestrians to stay clear of the gate's entire travel path. A separate pedestrian entry/exit must be clearly visible and promote pedestrian usage.

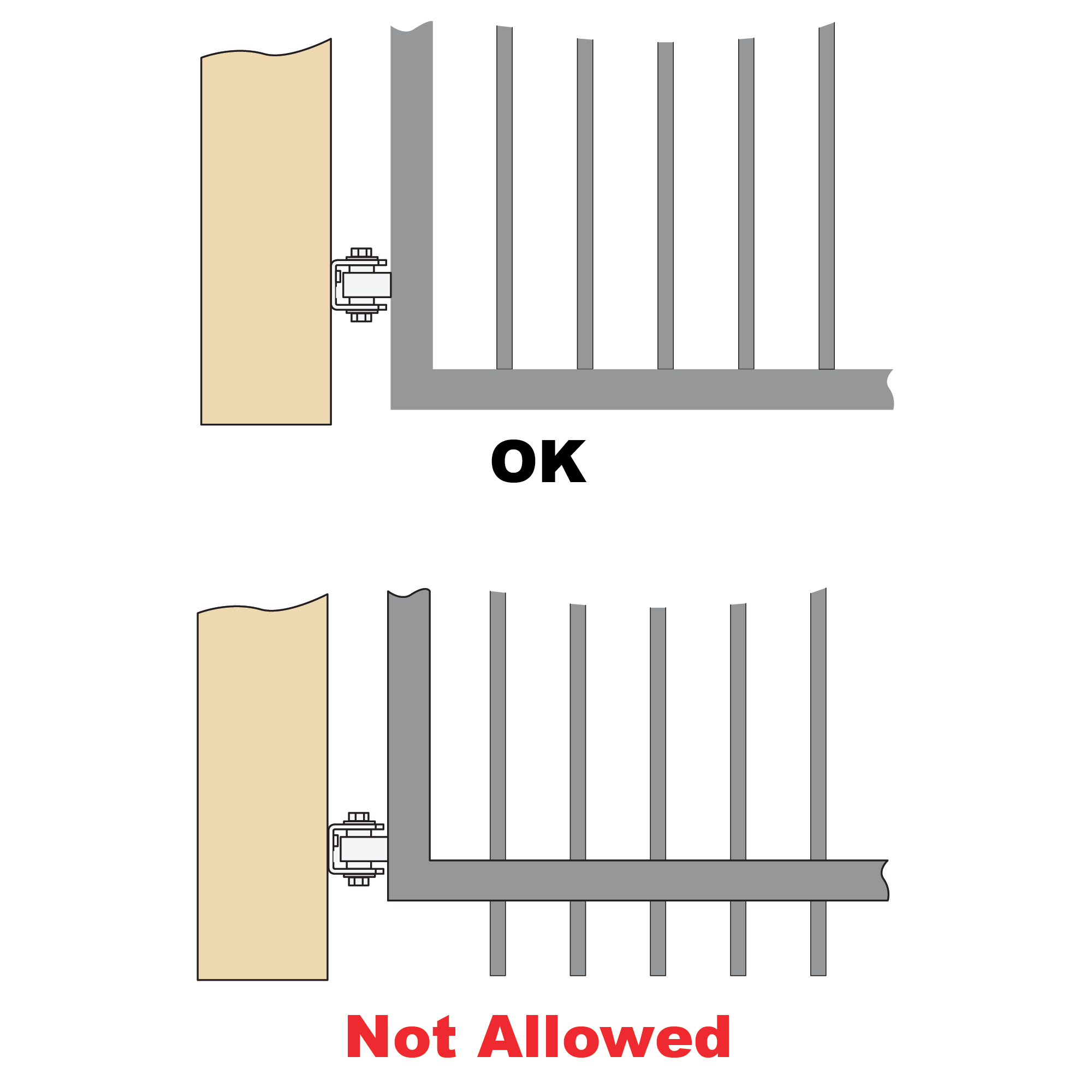

Hinge Mount Location: Entrapment Considerations

Slide Gate Requirements

Only install the operator on gates used for vehicular traffic. Be sure to direct pedestrians to a separate entry and exit. Refer to the illustrations. The gate sire must be designed, so persons do not come in contact with the vehicular gate while it is moving. Signs must be posted to warn pedestrians to stay clear of the gate's entire travel path. A separate pedestrian entry/exit must be clearly visible and promote pedestrian usage.

Base Of Swing & Slide Gates:

Gates must have smooth bottom edges; no protrusions should exist. If gate hardware or sensors protrude, they must have smooth surfaces free of any sharp cutting edges that do not exceed 1/2" (13mm) beyond the base of the gate.

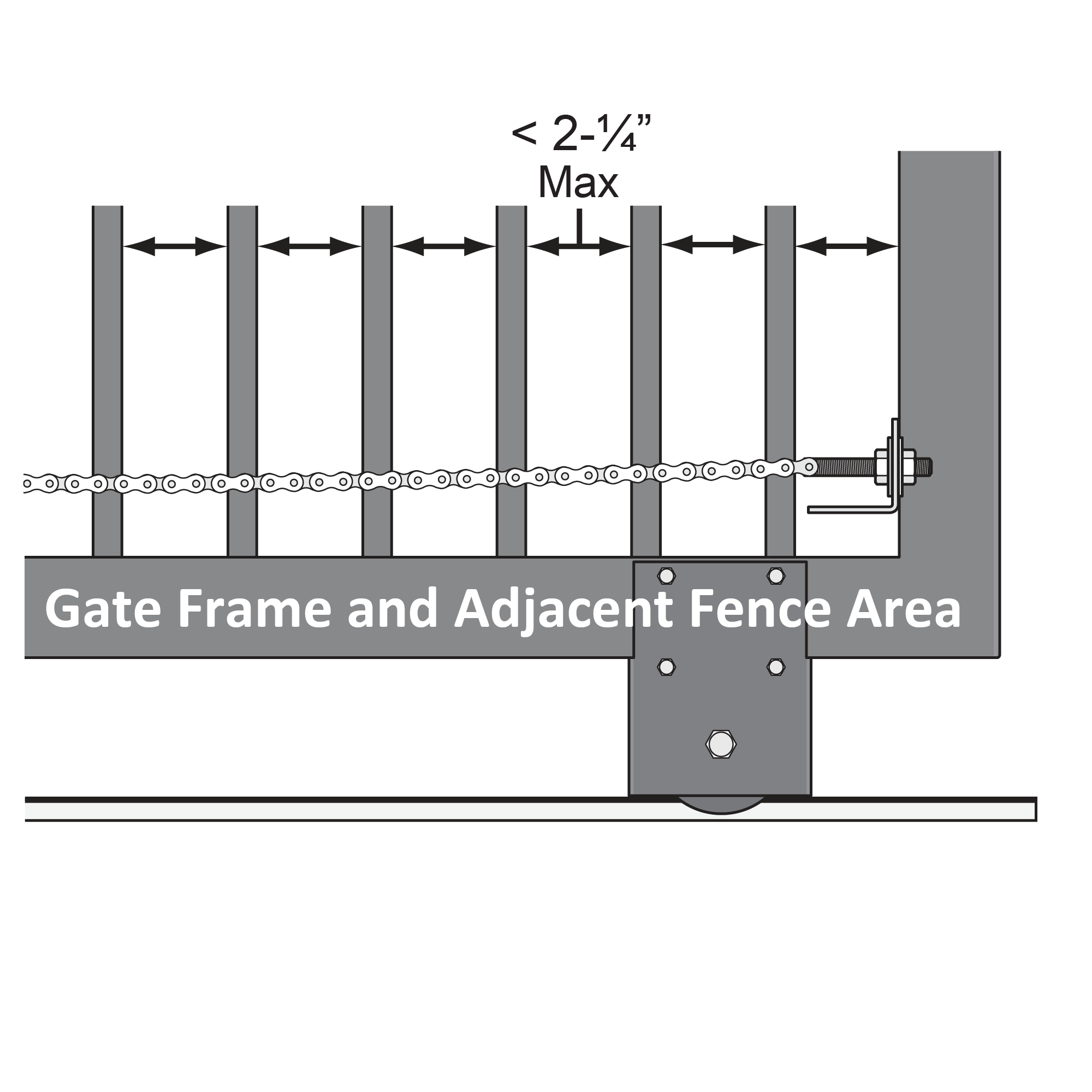

Compliant Openings: Picket Spacing

Gap between vertical bars must be less than 2 1/4 " (57 mm) up to a height of 6' (1.8 m) above grade.

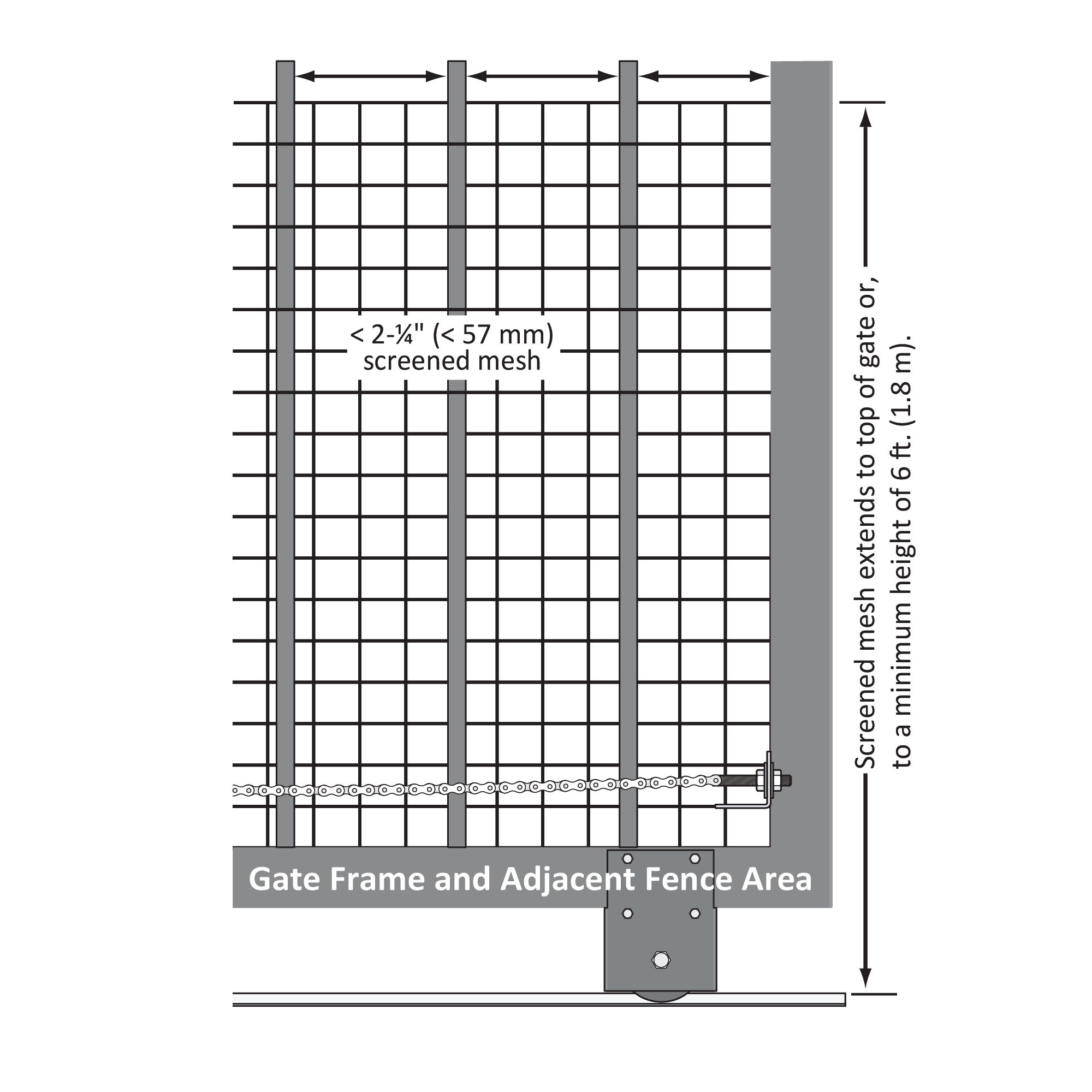

Compliant Openings: Screened Mesh

In the illustration below, the gap between vertical bars is non-compliant. It poses a safety hazard if it is 2 1/4" (57 mm) or wider. A screened mesh has been added to comply with ASTM F2200 and UL325 standards.

All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to the top of the gate or to a minimum of 6' (1.8 m) above the ground to prevent a 2 1/4" (57 mm) diameter sphere from passing through the openings anywhere in the gate and in that portion of the adjacent fence that the gate covers in the open position.

Be Aware:

Make sure your gate system is installed and maintained according to the manufacturer's instructions. Make sure your installer adheres to UL 325 and ASTM F2200 standards discussed in the Important Safety Instructions found in the operator's manual.

Do:

Review the illustrations found here for more information and safety requirements. Operate your gate system ONLY when all necessary entrapment protection devices are connected and working properly. Examples of these devices include edge sensors and photoelectric sensors. Follow ASTM F2200 standard for automated gates. Where applicable, these include the following:

All Gate Types

- No protrusions along the bottom of the gate.

- Fall-over protection to prevent the gate from falling when the gate is detached from supporting hardware.

Slide Gates:

- Covers for all exposed weight-bearing rollers and pinch points that exist less than 8' (2.5 m) above grade.

- Physical gate stops to avoid over-travel in both directions.

- Protective screen mesh to guard openings from the gate's base support to a minimum height of 6' (1.8 m) above the ground. This must prevent a sphere of 2 1/4" (57 mm) from passing through any opening in the gate or adjacent fence (the portion covered in the gate's open position.) Refer to the illustrations.

- A gap (measured horizontally, parallel to the roadway) between a fixed stationary object nearest the roadway and the gate frame shall not exceed 2 1/4" (57 mm) when opened or closed.

Be Safe!

Automated vehicular gate systems provide user convenience and security. However, because these machines can produce high levels of force, it is imperative that you understand how proper site design, installation, and maintenance reduce potential hazards associated with gates and automatic gate operators. Before the installer leaves the site, take a few minutes to inspect and test your gate system.

- Make sure your gate operator is grounded.

- If your operator is equipped with an Emergency Stop Switch, ask the installer where the Emergency Stop Switch is located and cycle the gate once or twice to test it.

- Learn how to power ON and OFF and manually open and close the gate.

- Inspect the entrapment protection devices. Ask your installer to perform tests and show you that they are working properly.

A Moving Gate Can Cause Serious Injury Or Death!

It is the owner's and user's responsibility to be aware of potential hazards associated with an automated vehicular gate system and take appropriate steps to reduce the risk of injury.

Be sure to read the important Safety Information found in your gate operator's manual as it provides more details and safety considerations than can be supplied here.

Notice: The design and construction of automated gates for vehicular traffic must comply with certain safety standards and local codes. The illustrations and callouts in these diagrams show the basics of gate system compliance.

Precautions For Gate Systems:

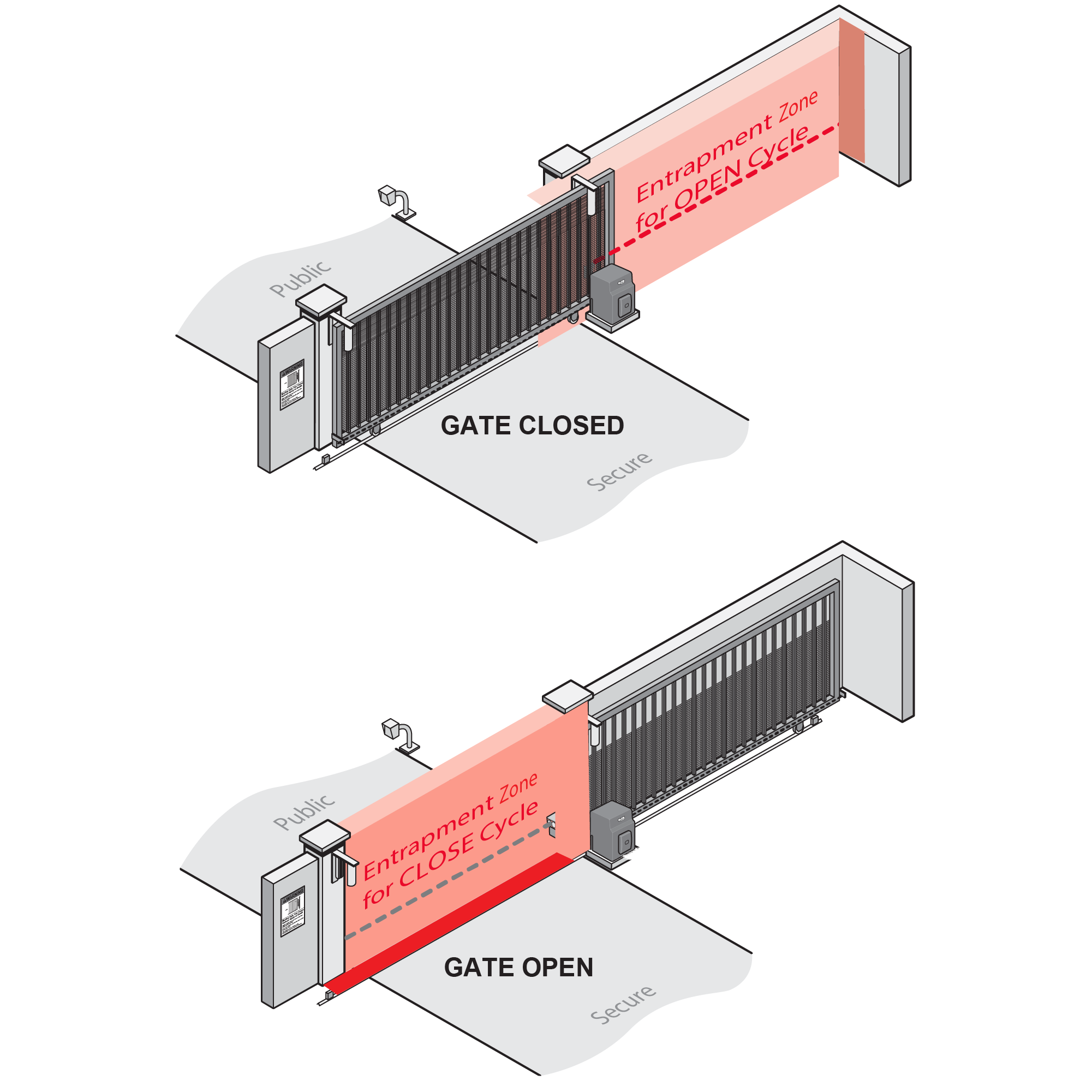

Entrapment Zone Hazards:

Body parts may become entrapped between a gate and a the stationary object when the gate moves, which can result in serious injury or death. Make sure pedestrians stay clear of the gate path and areas where gate motion is close to stationary objects.

Pinch Point Hazards:

- In open roller slide gates, severe injury can occur when hands and fingers get caught in the slide gate rollers. Feet can be injured between the bottom of the gate and bottom rollers. Make sure roller guards are installed to cover these pinch points.

- A swing gate’s opening mechanism may have arms that can overlap with a scissoring effect, which can result in serious injury. Make sure pedestrians stay clear of the gate path and the opening mechanism, especially when the gate is in motion.

Crush Hazards:

In picket gates, body parts are positioned between the bars, when the gate begins to move, can result in serious injury or death. Make sure openings are covered or screened and gaps are filled to prevent persons from reaching through, and/or passing through, the gate.

Safety Checklist:

- Automated gates are for vehicular use only; provide and maintain walkways and signs to direct pedestrians to a separate walk-through entrance

- Clearly display WARNING SIGNS on both sides of the gate in clear view.

- Never let children operate or play with gate controls.

- Keep all remote controls, especially radio transmitters, away from children. DO NOT allow children to play on or around the gate or gate operator.

- Make sure all access control devices are mounted at least 6 feet (1.8 m) away from any moving parts. Create a safe design where a person need NOT reach over, under, through or around the gate to operate the access controls

Installation & Maintenance

Follow the maintenance schedule recommended by the manufacturer and ask your qualified installer about a service agreement. On a regular basis:

- Check all entrapment protection devices in accordance with the manufacturer’s recommended maintenance schedule.

- Check that the gate is level. Manually open and close the gate to make sure it travels smoothly. (Refer to the gate operator’s manual to learn how to turn off power and move the gate by hand.)

- Check the gate hardware on a regular basis.

- Tighten any loose fasteners and replace any worn or damaged parts. A smooth-running gate prolongs the life of your gate operator.

- Before the qualified installer leaves the site, test all features (entrapment protection devices, obstruction sensing features) to make sure the gate stops and/or reverses upon sensing an object.

- Make sure you receive instructions on all operational functions of the gate operator. Learn how to reset the gate operator, turn on and off the power, and manually operate the gate.

Horizontal Slide Gate Systems

Swing Gate Systems

DASMA Operator & Electronics Data Sheets

TDS #350 - Garage Door Operator and Gate Operator Terminology

TDS #351 - Federal and State Garage Door Operator Legislation Guidelines for Dealers and Installers

TDS #352 - Automatic Vehicular Gate Operating Systems: Guidelines for Specifiers, Designers, Dealers, Installers and End Users

TDS #353 - Gate Operators and the ANSI/UL 325 Standard

TDS #354 - Loop Systems and Depth in Road Pavements

TDS #355 - Access Controlled Egress Doors

TDS #356 - UL 325 and Gate Installations - Frequently Asked Questions

TDS #358 - Vehicular Commercial Door and Gate Operators, and OSHA Requirements

TDS #359 - Gate Operators, Commercial Door Operators, and NEC Provisions

TDS #360 - Placement of Gate Operator Controls

TDS #361 - Garage Doors Operated in Tandem

TDS #362 - Residential Garage Door Operator Pre-Wiring Diagram

TDS #363 - Evaluation of Door or Gate Operators Employing Photoelectric Sensors

TDS #364 - Installation Location of Photoelectric Sensors on Residential Garage Doors

TDS #365 - Dimensions to Consider When Installing an Accessible Communications System

TDS #366 - Gate Operator Pre-Installation and Site Planning

TDS #367 - Testing of External Entrapment Protection Devices Used with Vehicular Gate Operators

TDS #368 - Edge Sensors

TDS #369 - Frequently Asked Questions Regarding Automated Residential Garage Door Systems

TDS #370 - Rationale Behind the Provisions of ASTM F2200

TDS #371 - Automated Vehicular Gate Systems: Checklist for Inspectors and Property Owners

TDS #372 - Rationale Behind Development of Provisions of DASMA 303 Performance Criteria for Accessible Communications Entry Systems

TDS #373 - Automated Vehicular Gate Systems: Checklist for Installers

TDS #374 - Door and Gate Operator Remote Control Troubleshooting Guide

TDS #375 - Motor Operated Commercial Sectional Doors and Rolling Doors: Typical Installation Concerns

TDS #376 - Automated Vehicular Gate System Warning Signs / Placards

TDS #377 - Selection, Placement, and Quantity of Photoelectric Eyes for Automated Vehicular Gates

TDS #378 - Automated Vehicular Gate System Emergency Access

TDS #379 - Telephone Entry/Access Control Systems Purposes, Types and Installation Basics

TDS #380 - Automated Vehicular Gate Systems and the Manual on Uniform Traffic Control Devices (MUTCD) - Frequently Asked Questions

TDS #381 - Rolling Doors Operated by Roller Chains

TDS #382 - Proper Installation of Photoelectric Non-Contact Sensors on Vehicular Commercial Door Operators

TDS #383 - ICC Model Code Content Involving Automated Vehicular Gate Systems

TDS #384 - Garage Door Operator Wall Control Button Mounting Height ADA Requirements and UL 325

TDS #385 - Opening a Motorized Garage Door to Exit a Home Through the Garage in a Power Outage

TDS #386 - Motorized Garage Doors Used In Entertainment Venues

Disclaimer: All customers and installers should check with UL (Underwriters Laboratories, Inc.) for the full UL 325 and DASMA listing and the most up-to-date regulations.

Other Safety Standards

DASMA Gate & System Information Sheet